General Features

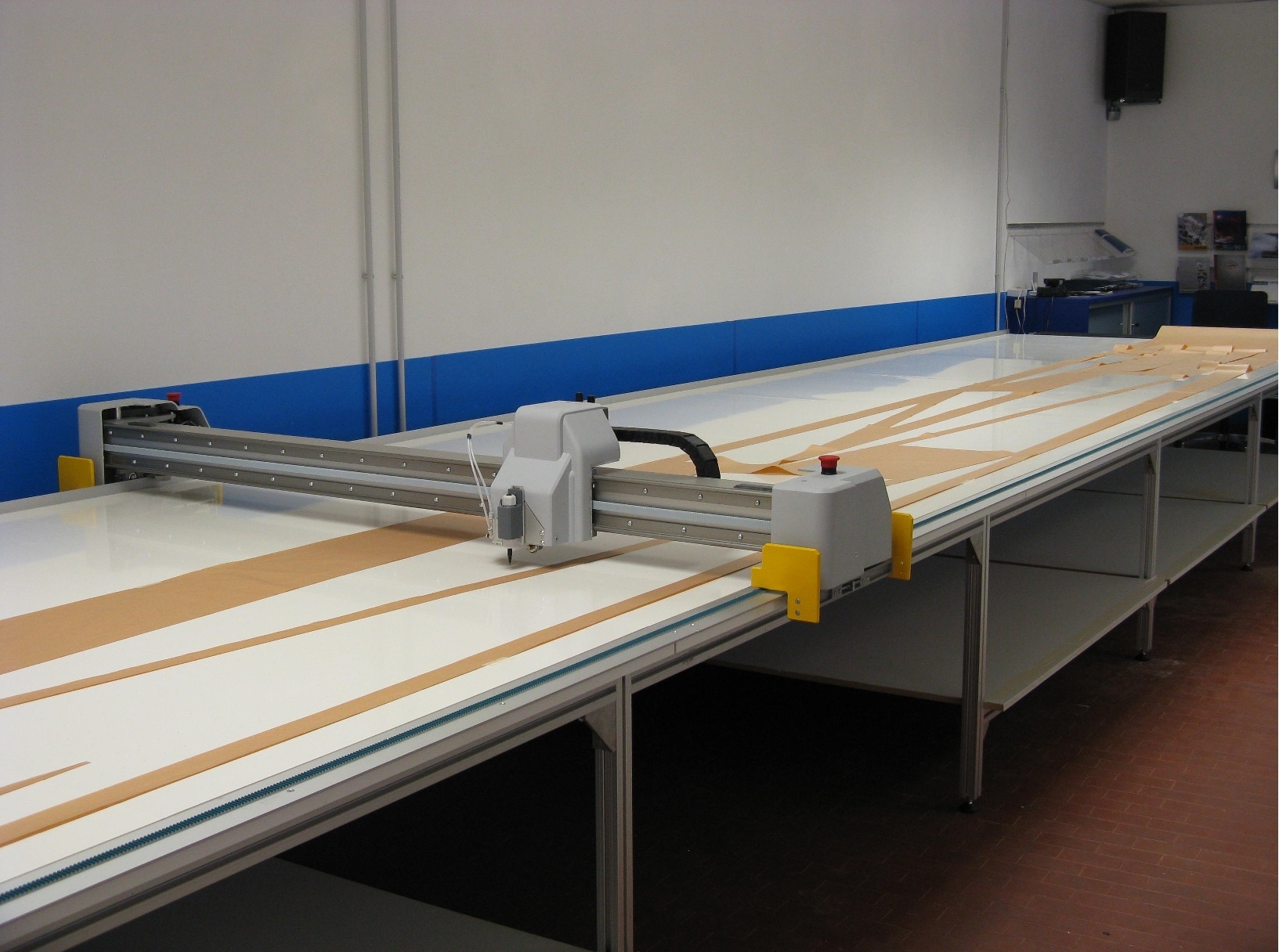

Maximum speed 1000 mm/s

Position accuracy less than max 0,5 mm

Hybrid high torque step motors

Custom working dimensions

Beam width can reach 6 meters

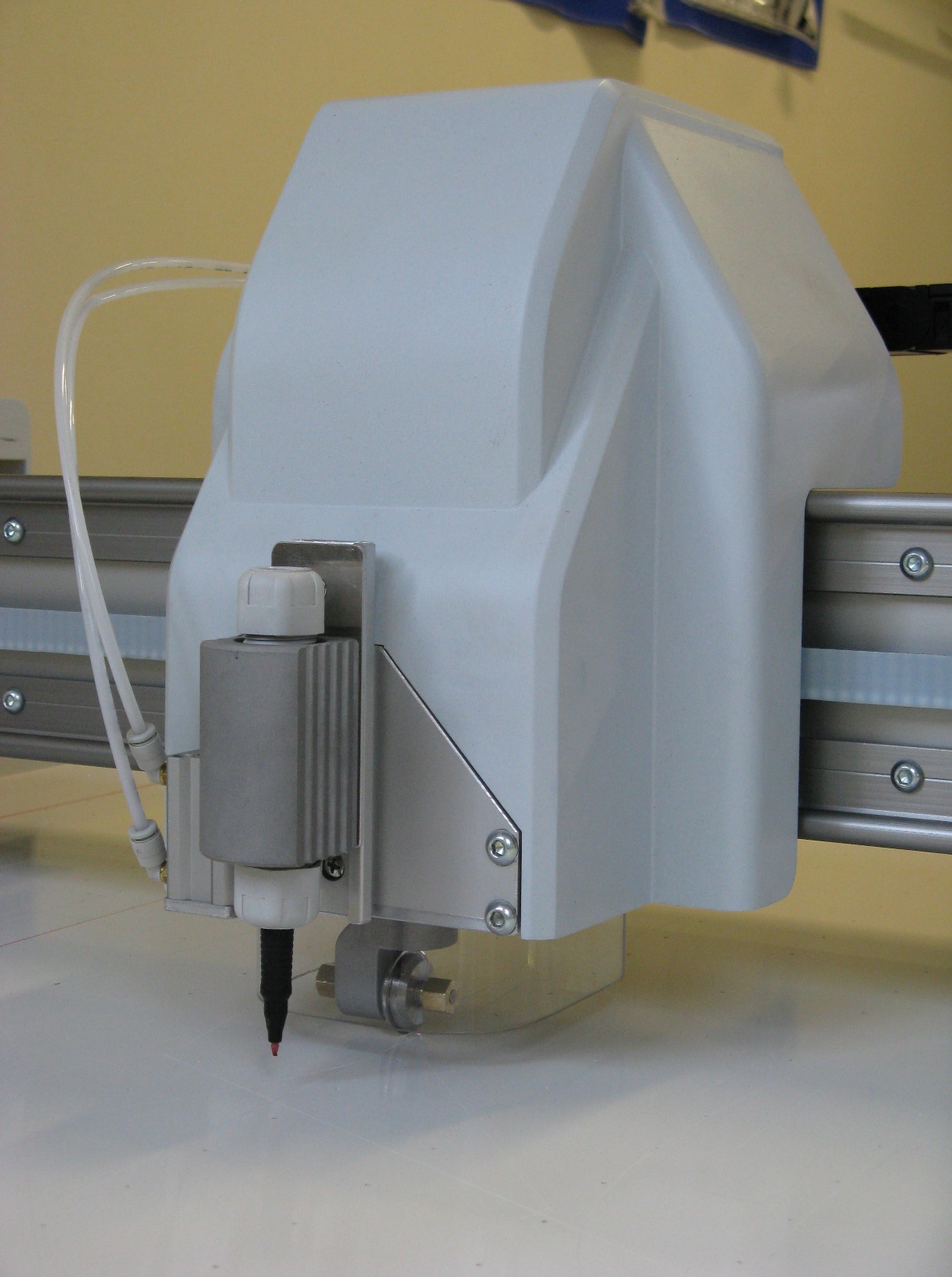

Universal pen holder

Circular blade 28 mm (standard)

Circular blade 18 e 45 mm (optional)

Tangential (Drag) blade (optional)

Adjustable cutting force (1-7 bar).

High thickness cutting capability

Human interface with local language

NTV or DXF AAMA for sailmakers

Standard DXF for CAD drawings

Easy manual nesting with mouse or keyb.

Panel sequencing feature

Digitizer (optional)

Vacuum table

Technical aluminium table structure

Vacuum force up to 4,5 Kg/dm2

Low maintenance costs

Low cost of ownership

CE marking

Competitive prices

|

|